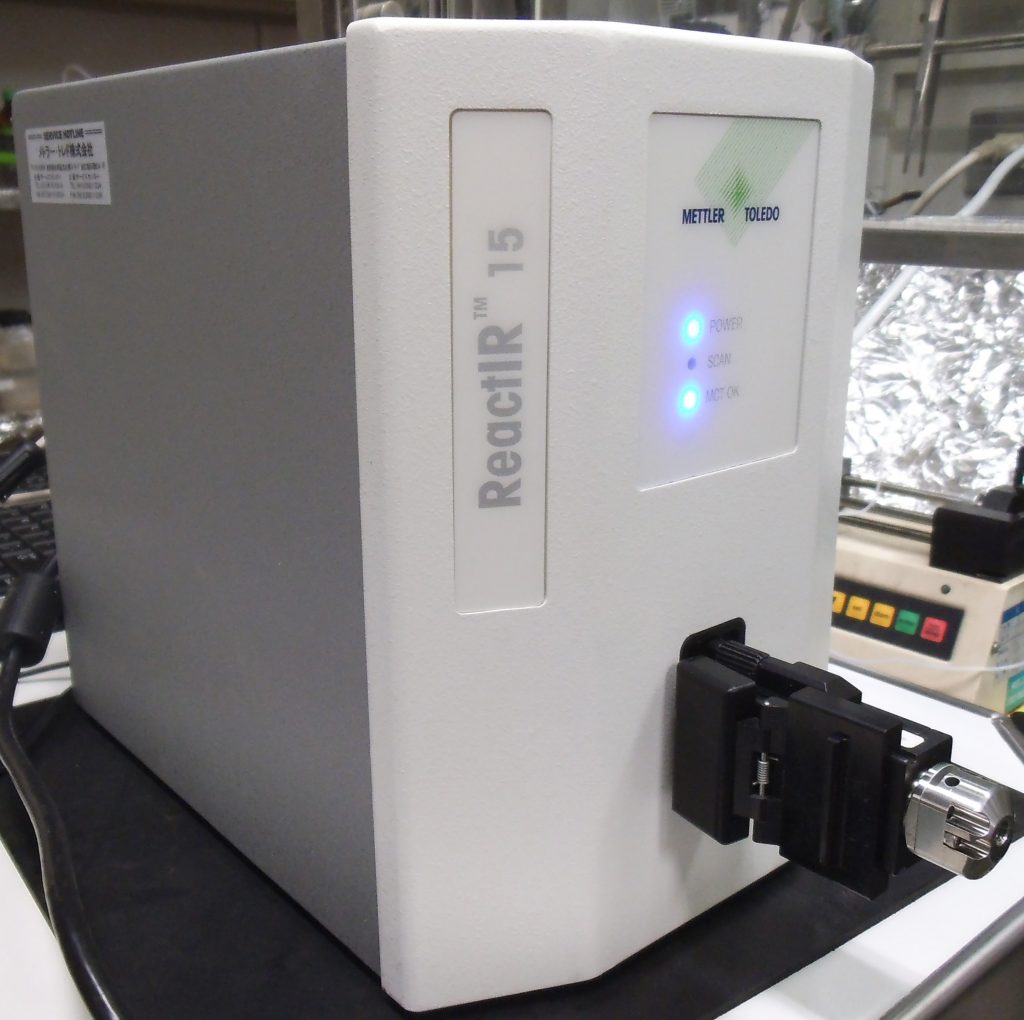

Combinations of in-line monitoring systems with continuous-flow systems enable rapid data acquisition. These technologies are not only valuable for rapid optimization of reaction conditions and for gaining insights into reaction mechanisms, but also for Quality by Design (QbD) based process control in future industrial-scale synthesis. Furthermore, the integration of machine-learning with continuous-flow synthesis and in-line monitoring technologies enables autonomous rapid optimization of processes. The COVID-19 pandemic has led to an increased focus on automated and remote synthesis in the field of organic chemistry. Originally, the affinity between continuous-flow synthesis and automated synthesis was high. Integrated continuous-flow technologies provide a strong boost to automated and remote synthesis. We have used these technologies for deeper understanding of synthetic organic chemistry and development of highly efficient synthetic processes.

We also develop efficient synthetic approaches for a variety of small molecules. In addition, we proceed collaborative works with companies to develop industrial processes. Our collaborator recently reported a development of the first continuous-flow, automated solution-phase peptide synthesizer. They also achieved the first real time monitoring of peptide bond formation using in-situ NIR analysis.

React. Chem. Eng. 6, (4) 863-870, (2023).